Practical advice for rendering and EWI application in cold and wet weather conditions

Cold, wet, and humid weather can significantly affect how render and EWI systems cure and perform. These conditions slow drying, weaken adhesion, and risk surface defects if not properly managed.

As a general rule, work should be suspended if temperatures are expected to fall below +5°C within 24–48 hours, or during periods of frost or heavy rain.

Baumit systems are designed for use within an ambient and substrate temperature range of +5°C to +30°C, unless using our designated cold-weather formulations.

Cement Based Products

e.g. Baumit StarContact, Ceramik Fix Adhesive, Ceramik F Pointing Mortar

Cement-based products cure through hydration, a chemical reaction that depends on moisture and temperature. When conditions are cold or damp, hydration slows dramatically, resulting in weaker adhesion and extended drying times.

Risks in Cold, Wet, and High-Humidity Conditions

Freezing:

If render freezes before reaching sufficient strength (≈5 N/mm²), expanding ice crystals cause cracking, flaking, and bond failure.

Slow Curing:

Below +5°C, hydration slows drastically. High humidity retains moisture, keeping render vulnerable to frost.

Lime Bloom / Efflorescence:

Cold, damp air allows soluble salts to migrate, forming a white powdery layer on the surface.

Colour & Texture Variation:

Uneven drying produces patchy or inconsistent finishes.

Necessary Precautions

Substrate:

Ensure dry, frost-free surfaces above +5°C.

Protection:

Use temporary enclosures (e.g. tented scaffolds, tarpaulins) to shield from rain and frost.

Accelerators:

Use approved non-chloride accelerators sparingly to speed up the set.

Warm Materials:

Store products in a dry, warm environment; use tepid water for mixing.

Ventilation with Heat:

Warm areas gradually and ventilate to prevent condensation.

Acrylic and Silicone Renders

e.g. Baumit GranoporTop, SilikonTop

Acrylic and silicone renders rely on evaporation to dry and form a durable film. Low temperatures and high humidity can prevent this, leaving the surface weak and unprotected.

Risks in Cold, Wet, and High-Humidity Conditions

Wash-Off:

Fresh render can be damaged by rain before forming a stable film.

Extended Drying Time:

High humidity slows evaporation, prolonging exposure to potential damage.

Film Formation Failure:

Below +5°C, acrylic particles cannot properly coalesce, leading to poor adhesion and cracking.

Trapped Moisture:

Applying topcoat over damp or uncured basecoats can trap moisture and reduce adhesion.

Necessary Precautions

Monitor Conditions:

Apply only between +5°C and +30°C, RH < 85%.

Use Winter Additives:

Baumit SpeedTop forms a protective skin on SilikonTop and GranoporTop from 1degC, becoming rainproof within a few hours and allowing the topcoat to cure naturally.

Cure Basecoats Fully:

Ensure primers and basecoats are completely dry before applying topcoat.

Physical Protection:

Use breathable sheeting to prevent rain contact while maintaining airflow.

Timing:

Work during the warmest and driest part of the day.

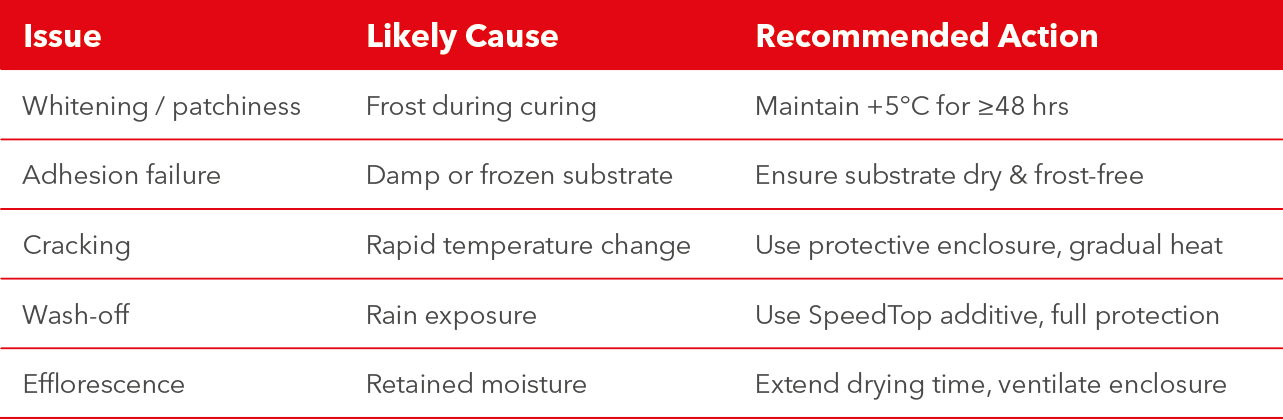

Common Issues and Prevention

Issues, likely causes & recommended actions

Cold-Weather Solutions from Baumit

When conditions make standard materials unsuitable, Baumit offers special cold-working products that maintain performance and curing reliability.

Baumit StarContact Speed

Fast-setting mineral adhesive and basecoat for use in cold and humid environments (+1°C to +10°C).

Suitable for bonding and basecoating within Baumit EWI systems (excluding plinth areas) and directly onto masonry.

Baumit SpeedTop

Cold-weather additive for SilikonTop and GranoporTop renders.

Allows safe curing at temperatures from +1°C to +15°C, and relative humidity up to 95%.

Baumit SpeedTop Star

Cold-weather additive for StarTop.

Ready to use additive for StarTop. Forms a protective skin on the facade guarding against humidity and allowing renders to cure at lower temperatures. Can be added in temperatures of +1°C and 15°C and with relative humidity of <95%.

Key Features:

- High adhesion and flexibility

- Vapour-permeable and water-resistant

- Quick setting and excellent workability

- Not to be mixed with antifreeze or unapproved accelerators

Typical Application:

- Apply as adhesive (5 mm) or as basecoat (3–5 mm) with embedded Baumit StarTex mesh.

- On masonry, apply in two passes of 5 mm (total 10 mm).

- Working time: approx. 45–60 minutes below 10°C.

Key Features:

- Forms a temporary protective skin, protecting against humidity and light rain.

- Ensures film formation even in colder conditions.

Ready to use — simply mix into the topcoat.

Note: Only suitable for SilikonTop and GranoporTop.

Key Features:

- Cold working additive.

- Ready to use.

- Forms protective skin on topcoat.

Note: SpeedTop Star cannot be used with silicate plasters as the additive is only suitable for Baumit StarTop.

Additional Info

When to postpone work

In extreme cold, heavy rain, or persistent high humidity (>85%), postponing work remains the most reliable option to prevent rework, aesthetic defects, and compromised long-term durability.

Technical Support

For specific project advice or product recommendations, please contact:

technical@baumit.co.uk

01622 710 763